2022 wholesale price Sus440c Stainless Steel Balls - 440 stainless steel balls high quality precision – Mingzhu

2022 wholesale price Sus440c Stainless Steel Balls - 440 stainless steel balls high quality precision – Mingzhu Detail:

440 stainless steel balls combine the remarkable hardness with the great resistance to corrosion caused by water, steam, air as well as by gasoline, oil and alcohol. High degree of surface finish and very precise size tolerances make this type of stainless steel are the best for the usage in stainless steel high precision ball bearings, valves, ball pens.

Specification

|

440 stainless steel balls |

|

|

Diameters |

2.0mm – 55.0mm |

|

Grade |

G10-G500 |

|

Application |

ball bearings, oil refinery valves, ball point pens |

Hardness

|

440 stainless steel balls |

|||

|

According to DIN 5401:2002-08 |

According to ANSI/ABMA Std. 10A-2001 |

||

|

over |

up to |

|

|

|

all |

all |

55/60 HRC |

55/62 HRC |

Equivalence Of Material

|

440 stainless steel balls |

|

|

AISI/ASTM(USA) |

440B |

|

VDEh (GER) |

1.4112 |

|

JIS (JAP) |

SUS440B |

|

BS (UK) |

- |

|

NF (France) |

- |

|

ГОСТ(Russia) |

- |

|

GB (China) |

- |

Chemical Composition

|

440 stainless steel balls |

|

|

C |

0.85% - 0.95% |

|

Si |

≤1.00% |

|

Mn |

≤1.00% |

|

P |

≤0.04% |

|

S |

≤0.015% |

|

Cr |

17.00% - 19.00% |

|

Mo |

0.90% - 1.30% |

|

V |

0.07% - 0.12% |

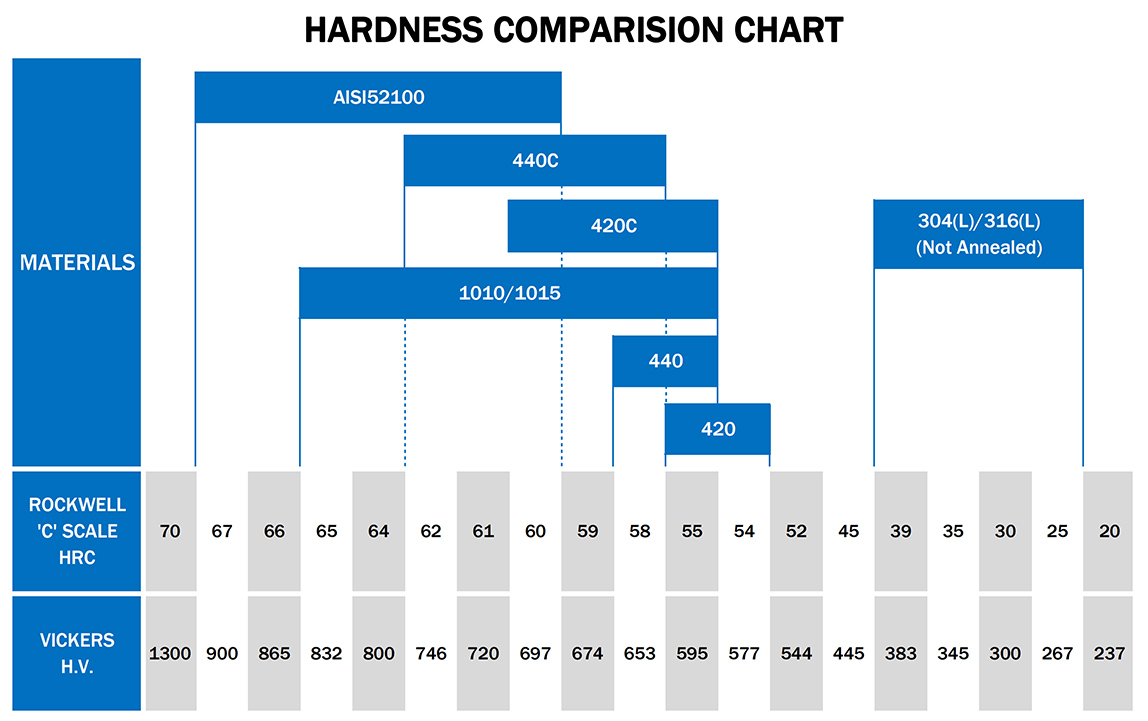

Hardness Comparision Chart

Our Advantage

● We have been engaged in steel ball production for more than 26 years;

● We offer a great variety of sizes ranged from 3.175mm to 38.1mm. Non-standard sizes and gauges can be manufactured under special request (such as 5.1mm, 5.15mm, 5.2mm, 5.3mm 5.4mm for seat track; 14.0mm for cam shaft and CV joint, etc.);

● We have a wide stock availability. Most of the standard sizes (3.175mm~38.1mm) and gauges (-8~+8) are available, which can be delivered immediately;

● Each batch of balls is inspected by sophisticated machines: roundness tester, roughness tester, metallographic analysis microscope, hardness tester (HRC and HV) to guarantee the quality.

FAQ

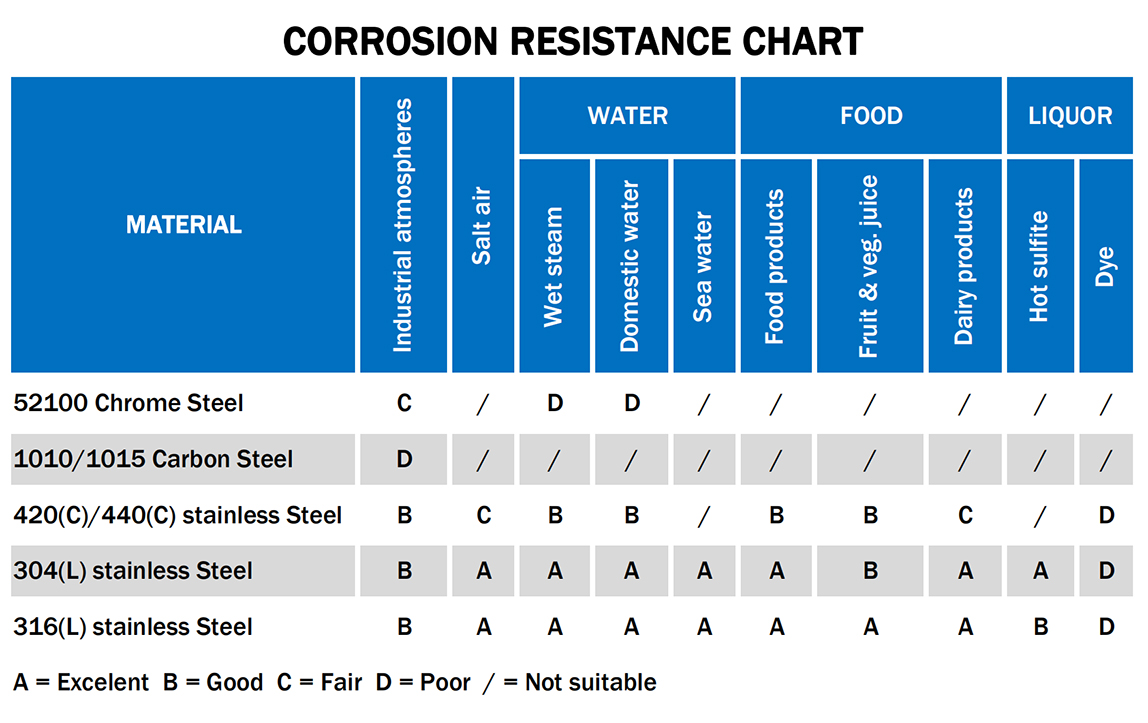

Q: How do I choose the appropriate stainless steel brand (304(L)/316(L)/420(C)/440(C))? What are the main differences between 300 and 400 series stainless steel balls?

A: To choose the proper steel brand for stainless steel balls, we should get to know well the properties of each brand and the application of the balls. The most common used stainless steel balls can be divided simply in two groups: 300 series and 400 series.

300 series “austenitic” stainless steel balls contain more chromium and nickel elements and are theoretically non-magnetic (actually are very low-magnetic. Totally non-magnetic require additionally heat treated.). Normally they are produced without the heat treatment process. They have better corrosion resistance than 400 series (in fact, the highest corrosion resistance of the stainless group. Although 300 series balls are all quite resistant, however 316 and 304 balls show different resistance to some substance. For more details, please refer to pages of different stainless steel balls) . They are less brittle, so can be applied also for sealing use. 400 series stainless steel balls contain more carbon, which makes it magnetic and more hardness. They can be easily heat treated like chrome steel balls or carbon steel balls to increase hardness. 400 series stainless steel balls are commonly used for applications that demand water-resistance, strength, hardness and wear resistance.

Q: How is your quality assurance?

A: All produced balls are 100% sorted by the sorting bar and checked by the photoelectric surface defect detector. Before packaging samples balls from the lot are to send for final inspection to check for the roughness, roundness, hardness, variation, crush load and vibration in compliance with the standard. If all requirements are met, a inspection report will be made for the customer. Our sophisticated laboratory is equipped with high precision machines and equipment: Rockwell hardness tester, Vickers hardness tester, crushing load machine, roughness meter, roundness meter, diameter comparator, metallographic microscope, vibration measuring instrument, etc..

Product detail pictures:

Related Product Guide:

Our merchandise are broadly identified and trusted by end users and can satisfy continually developing economic and social requires for 2022 wholesale price Sus440c Stainless Steel Balls - 440 stainless steel balls high quality precision – Mingzhu , The product will supply to all over the world, such as: Switzerland, Cancun, Uganda, we have all day online sales to make sure the pre-sale and after-sale service in time. With all these supports, we can serve every customer with quality product and timely shipping with highly responsibility. Being a young growing company, we might not the , but we are trying our to be your good partner.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!

Products categories

-

Phone

-

E-mail

-

Whatsapp

-

Skype

-

Top