Quality

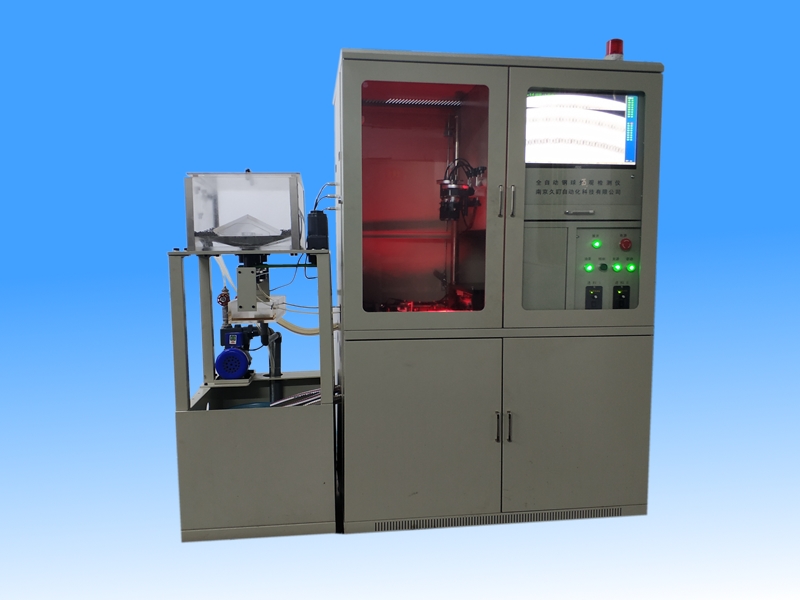

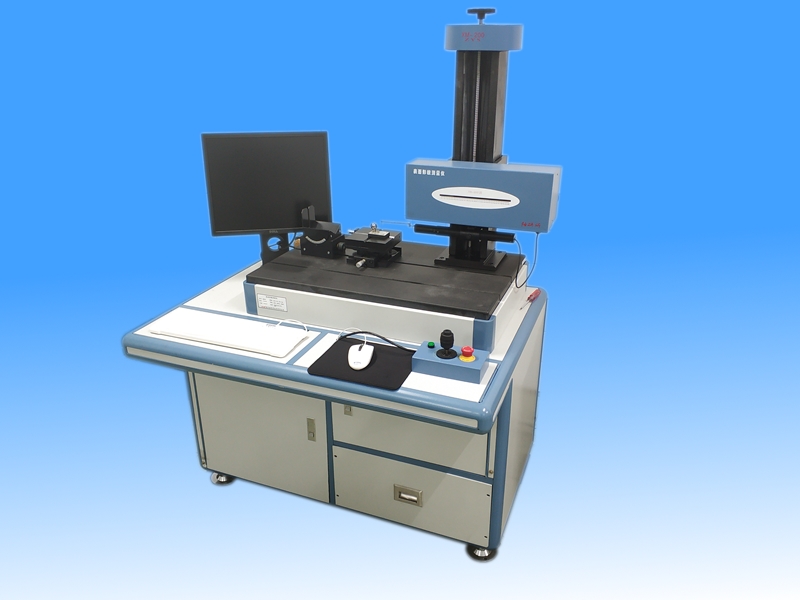

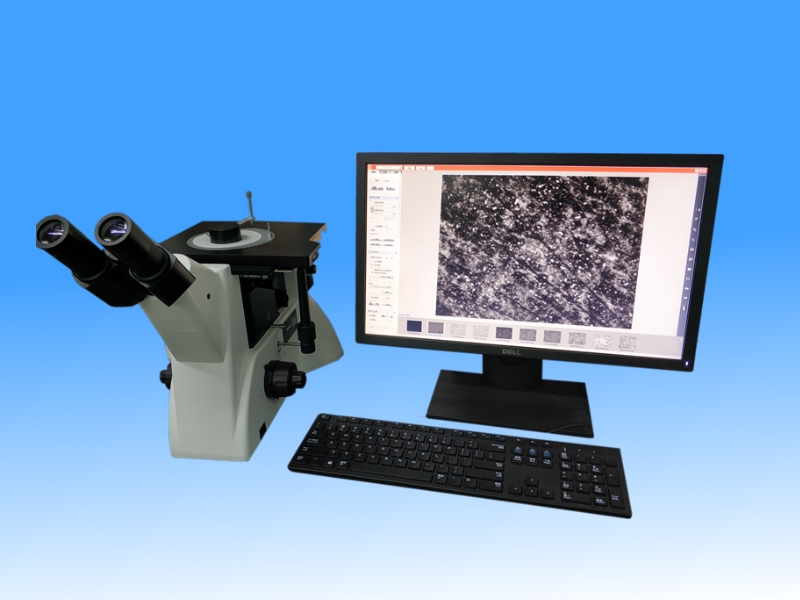

Our balls are sorted by the sorting bar and checked by the optical surface defect detector. Before packaging samples balls from the lot are to send for final inspection to check for the roughness, roundness, hardness, variation, crush load and vibration in compliance with the standard. If all requirements are met, a inspection report will be made for the customer. Our sophisticated laboratory is equipped with high precision machines and equipment: Rockwell hardness tester, Vickers hardness tester, crushing load machine, roughness meter, roundness meter, diameter comparator, metallographic microscope, vibration measuring instrument, etc..

1. Optical surface defect detector

2. Roughness meter

3. Roundness meter

4. Hardness tester

5. Metallographic microscope

6. Crush load tester

7. Vibration tester